Since version 1.52c33

The page explains the details of the automatic error reset mechanism introduced in Shark2a firmware versions V1.52c33 and higher. The automatic reset is configured as default for error 30 “Detector Clipping” and is permanently enabled for error 14 “Receiver Clipping”.

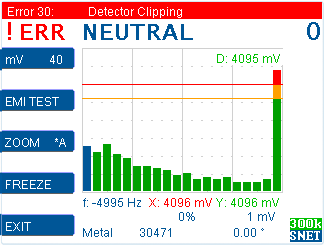

Why is Error 30 occuring?

Error 30 means that the receiver coil sends such a large signal to the amplifier, that the amplifier comes to his upper voltage limit. The signal is getting clipped off, or it reaches the ceiling. This is kind of dangerous, because it can lead to metal passing through undetected.

The reason for such a big signal can be a real large metal object. Or a super strong product effect, like a container filled with raw bloody meat or a salt soaked pork ham.

How to reduce or prevent Error 30

Set DIP switch 2 = On

Go to UTILITIES menu (you will need the LEVEL4 password for this)

Set ATTENUATION FIXED = 1/10

This divides all receiver coil amplitudes by 10.

Note – Also all metal mV signals will be divided by 10. To obtain same detection sensitivity as before, you shall set these settings to approximately 1/10 of the previous mV setting. After, perform a new teach.

SENSE MIN mV https://docs.cassel-inspection.com/md/teach-setup

TEACH SENSE mV https://docs.cassel-inspection.com/md/teach-setup

METAL SENSE mV https://docs.cassel-inspection.com/md/metal-sense-mv

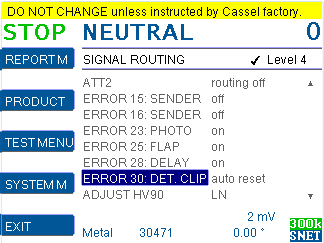

Enable / Auto Reset / Disable Error 30

Since 1.52c33 a setting in the FACTORY MENU>UTILITIES>SIGNAL ROUTING menu allows to change the behaviour of Error 30. Note that access to the UTILITIES requires DIP2 = ON at the mainboard.

ERROR 30 DET. CLIP = on:

Once error 30 has been triggered, it will remain until the user acknowledges it by pressing the OK button or a 24V input set as “met/err reset”. This is the behavior as preset in previous firmware versions.

ERROR 30 DET. CLIP = off:

The error 30 will never trigger – even if the detector hardware is saturated and while saturated unable to detect metal – therefore this setting is not recommended.

ERROR 30 DET. CLIP = auto reset:

After error 30 is triggered, the firmware continues to check the error condition and automatically resets error 30 once the saturation has disappeared. During the auto-reset, the firmware can initiate a quick auto-calibration.

As long as the Error 30 condition exists, the metal detector is in error mode. The error outputs are active:

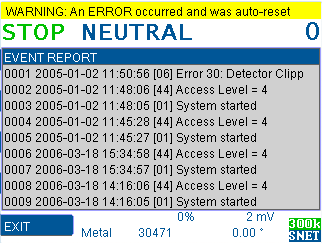

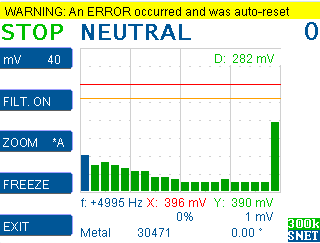

After the automatic reset, the event report opens automatically and a yellow warning informs the user that an error has occurred. The user can press the ESC key to return to the main screen:

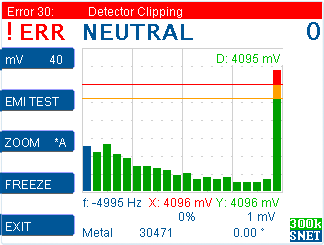

If another error 30 occurs within 10 minutes, which is also automatically reset, the event report does not open automatically so as not to affect menu navigation/operation. The warning continues to be displayed to inform that an error has occurred which has been automatically reset:

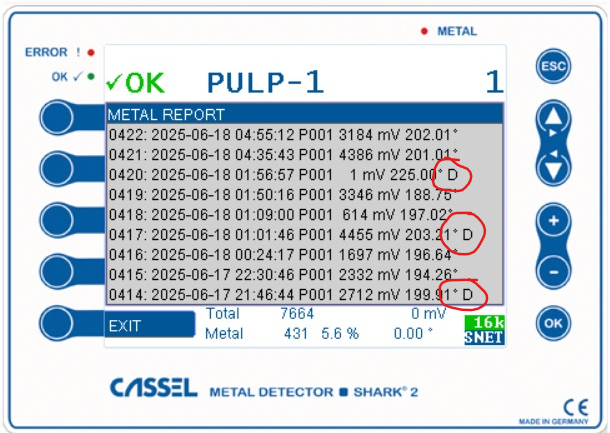

Diagnose with the Metal Report

Open MENU > REPORT > METAL REPORT

Metal events that are marked with a ‘S’ or ‘D’ character:

‘S‘: Metal amplitude after amplification got saturated. The metal amplitude was so big that the AD converter got saturated – in this case a metal alarm is generated even if the filtered signal is inside the teach area. Such a metal amplitude results only from very large metal objects.

Note – The metal amplitude is depending on the amplifications X% and Y%. Lower amplification% results in less metal amplitudes.

‘D‘: Metal amplitude before amplification got saturated. Metal amplitude was so big that it got saturated even before the amplifiers. Such a metal amplitude results only from exceptional large metal objects. In this case is also a metal event generated (even is it is inside teach area).