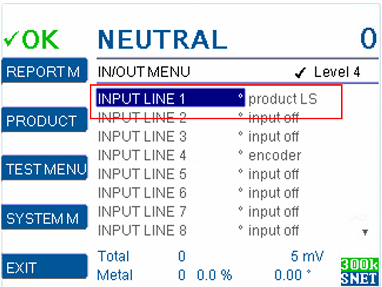

- Go to SYSTEM MENU > IN OUT MENU

- Set INPUT = product LS

Input ‘product LS’ has two different functions, depending on the metal detector (MD) type. The MD type is set in the software by the profile. FACTORY MENU > UTILITIES > SET PROFILE.

Profile (MD type) = BD

‘product LS’ counts the product packs that are passing through the MD. With profile = BD you can set any of the INPUTs 1 to 8 = product LS.

Input ‘product LS’ = HIGH is when the photo beam is not interrupted

Input ‘product LS’ = LOW is when the photo beam is interrupted

A HIGH – LOW – HIGH pulse increase the product counter by 1.

NOTE #1 – ‘product LS’ shall not be used together with the input ‘reject sync’. Because reject sync has the product counting included.

NOTE #2 – Use ‘product LS’ only together with PRODUCT MENU > REJECT MENU > METAL CONTACT = pulse or push3. Refer to PRODUCT MENU > REJECT MENU > METAL CONTACT

Profile (MD type) = COMBI

‘product LS’ resets the encoder counter (also called the product length counter). With profile = COMBI set only INPUT 1 = product LS.

This setting requires 24V (high) input. A pulse low – high – low resets the encoder counter to 0. The high signal must be minimum 2000 ms.

Provide the reset signal before or at the start of a new roll or a cutter signal. The encoder counter determines the Y position (distance since roll start) of a metal object. A new roll shall start with encoder position = 0.

Set an offset for the reset position:

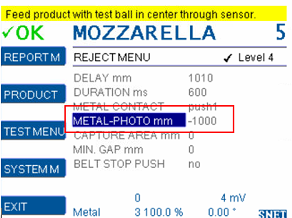

- Go to PRODUCT MENU > REJECT MENU > METAL PHOTO mm

- Set METAL-PHOTO mm

The offset METAL PHOTO mm has this effect:

metal_pos_product = metal_pos_sensor – metal_photo_mm

metal_pos_product = Y distance of the metal detection from the roll start (from last reset)

metal_pos_sensor = Encoder position on metal detection at the COMBI sensor position

metal_photo_mm = METAL PHOTO mm (offset distance), a positive number delays to after the COMBI sensor