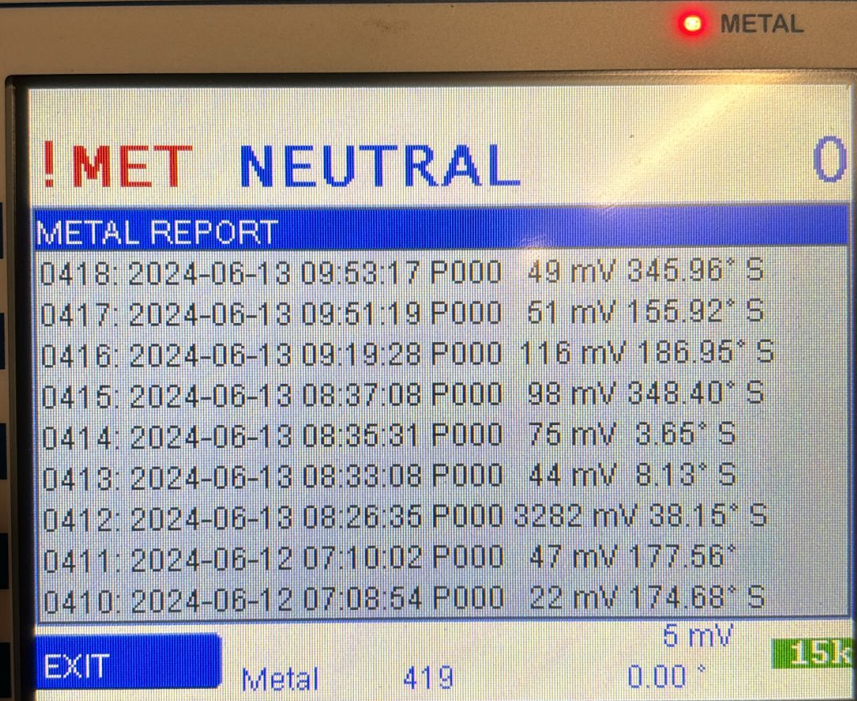

Characters at the end of a metal report line are for diagnose purposes:

D = Detect M Signal Clipping (directly at the receiver coil).

The signal at the demodulators is so large that they saturate (and can even be rendered blind).

Display of Detect M signal in the upper right corner of EMI screen for user level 4.

R = RFP Clipping

The input amplifier at the receiver coil input is saturated (measurement at amplifier output).

S = Saturated raw signal at the A/D converter.

! = with photo sensor: Metal detection without a suitable photo sensor interruption in this area.

Also refer to Error 23.

Priority of metal alarm markers is ‘D’ > ‘R’ > ‘!’ , so satured signal info is displayed prioritized to ! metal detections without a suitable photo sensor interruption.

What to do in these cases with D, R, S:

Problem as described by the customer:

Our customer has had some problems lately with the detector as it will signal a metal detection although the signal doesn’t exceed the limit value.

Reason for this behavior:

The signal path from the sensor head (or the search coil) to the electronics is getting saturated by a high frequency noise signal. The METAL REPORT shows more info with a character at the end of a detection line.

What means saturation?

Saturation means that the electrical mV signal is becoming that strong that is exceeds the measurable range. Saturation has an external root cause, outside of the metal detector. The metal detector itself works as intended.

Where does such strong signal origins from? Examples:

High signal level (metal-packed product or large packages with brine).

Strong EMI (also at completely different frequencies than the detection frequency, up to >10 MHz).

Motors that are driven by a VFD, and the motor cable lacks a shielding braid.

The shielding braid is not tied to ground on both cable ends.

The VFD’s are not equipped with the motor filters on motor and power supply side, as recommended by the VFD manual.

The VFD’s or the metal detector are missing ground potential.

What can a customer do to solve this?

Decrease AMPLIFICATION % for X and Y and set an ATTENUATION of 1/3. Check the online documentation:

https://docs.cassel-inspection.com/md/amplification-x-y

https://docs.cassel-inspection.com/md/attenuation

Particular drastic cases: Use an external attenuator.

How can Cassel support?

Cassel can check the nature of the noise by remote support. Please contact us if you want this. Customer needs to prepare a Laptop with Teamviewer acccess.

The metal detector has a diagnose screen included to show high freq noise. That is the EMI screen, refer to attached bulletin.

The online diagnose could be turning on/off all surrounding motors and see which provides the noise.