Error 23 is raised if:

Case 1:

An output is set to ‘conveyor start’ or AUTOSPEED = yes.

The ‘reject sync’ photo beam is permanently interrupted for a long time, eg. because the photo lense is dirty with dust, or the photo sensor is miss-aligned, or a product jam occured, or its a long product that is longer than the length as set in ‘PHOTO EYE ERR mm’.

‘PHOTO EYE ERR mm’ sets how much the conveyor must move forward while the photo beam is broken, until ERROR 23 is triggered. The distance ‘PHOTO EYE ERR mm’ is calculated from the SPEED mm/sec setting. ‘PHOTO EYE ERR mm’ = 0 disables ERROR 23 detection. ERROR 23 is self resetting after the photo beam becomes uninterrupted – however the conveyor has to be restarted manually.

Read more about how to set PHOTO EYE ERR mm:

https://docs.cassel-inspection.com/md/brc-menu

Case 2:

An output is set to ‘conveyor start’ or the setting AUTOSPEED is yes.

And METAL CONTACT is either push1 or push2.

And at least five (5) or more products have passed (or noise signals have been detecetd) without interrupting the photo beam.

The mV signal of these products must exceed the threshold TEACH SENSE mV. The error resets after a product properly interrupted the photo beam and then passed the BD sensor (case 2/ is available since firmware 1.50b).

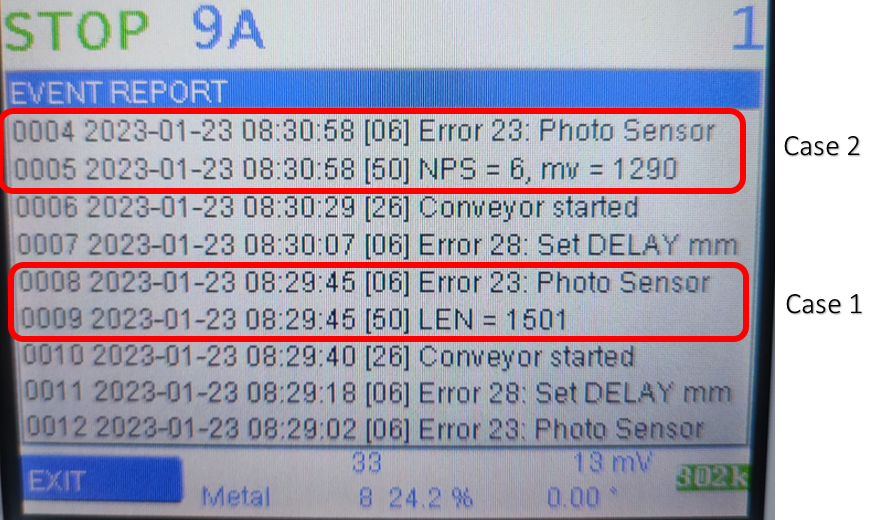

Since version 1.52c08 more information about what triggered error 23 is shown in

Open MENU > REPORT MENU > EVENT REPORT:

In the above example for Case 2:

NPS=6, mv=1290 tells that there occured six metal detections without interrupting the photo eye beam. The strongest detection had an amplitude of 1290 mV.

In the above example for case 1:

LEN = 1501 tells that the photo beam got interrupted for the duration that is equal to a conveyor forward moving length of 1501 mm. The length is calculated from the metal detector SPEED mm/sec setting.

How to solve:

Check the photo sensor (PEC) that is connected to ‘reject sync’ or ‘product ls’ input. Typically this photo sensor is installed before the BD sensor head (with conveyor systems).

Also check if any dirt spots in belt or any noise goes above TEACH SENSE mV.

How to solve: Set SENSE MIN and TEACH SENSE, to consider the dirt spots in the belt

Open MENU > PRODUCT MENU > TEACH SETUP

Move cursor to SENSE MIN mV

Start conveyor

Wait a while, until belt has fully rotated for at least 3x. The Shark measures the noise that comes from the conveyor.

Set SENSE MIN mV same as suggested in the yellow notification bar.

Set TEACH SENSE mV the same.

https://docs.cassel-inspection.com/md/teach-setup

Compare ‘PHOTO EYE ERR mm’ and product length

‘PHOTO EYE ERR mm’ must be set to at least 2 times the maximum product length that passes through this metal detector.

Read more about how to set PHOTO EYE ERR mm:

https://docs.cassel-inspection.com/md/brc-menu

How to disable error 23

Warning: Disabling the error 23 can lead to the situation where the metal detection function is disabled and no metal is detected! This happens when the error 23 condition is true. It is recommended to keep error 23 enabled at all times.

Open FACTORY MENU>UTILITIES>SIGNAL ROUTING

Set ERROR 23: PHOTO = off