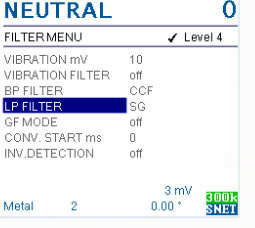

The FILTER MENU sets filters to improve the detection reliability and suppress noise.

VIBRATION mV

To set VIBRATION mV:

- Set PRODUCT 000, AMP X% 100, AMP Y% 100

- Run the production line or the conveyor, but without products and without metal.

- Read out the peak mV level.

- Set VIBRATION mV to the maximum peak mV level plus 30%

Default: 10

Range: 0 – 2,000

VIBRATION FILTER

blanks out mechanical vibrations of the sensor head.

yes activates vibration filter.

The value of VIBRATION mV (above) controls the filter strength:

VIBRATION mV increased: Better suppression of vibration noise, less detection sensitivity.

VIBRATION mV decreased: Less suppression of vibration noise, better detection sensitivity.

Default: no

BP FILTER

Note: Only change this filter when advised by CASSEL.

no filter = filter is deactivated. Do not use unless clearly instructed by CASSEL

FFT = special filter mode. Do not use unless clearly instructed by CASSEL

CCF = default

CounterX = special filter mode. Do not use unless clearly instructed by CASSEL.

Default: CCF

LP FILTER

SG = Lowpass filter activated. Improved noise cancelation, since version 1.50a.

FIR = Lowpass filter activated. Included for backward compatibility reason. FIR was used with LP FILTER = yes in older software versions before 1.50a.

no filter = Lowpass deactivated

Default: SG

GF MODE

yes enables fast metal detection. Gives a wide speed range (for GF or fast applications).

no is used for normal applications

Default: no

Range: no (conveyor applications with defined belt speed)

yes (applications with undefined speed)

yes (all gravity feed applications)

CONV. START ms

Duration of metal alarm blank out after conveyor start.

Set the duration after conveyor start for which metal contaminated products will not be detected.

Range: 0-9999 ms

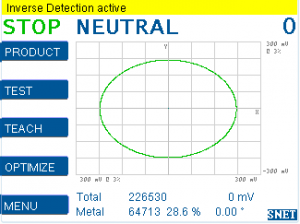

INV. DETECTION

Inverse detection changes the function of the SHARK2 metal detector so that all products are rejected that do NOT contain metal.

The detection is completely inverted. This means that:

TEACH: during TEACH pass products WITHOUT metal.

METAL COUNTER: counts products WITHOUT metal.

METAL REPORT: the metal report shows events WITHOUT metal

SHARKNET: In the SHARKNET non-metal events get reported

For further information refer to:

https://docs.cassel-inspection.com/md/howto-inverse-detection