Settings for detection of all products that do NOT contain metal.

Note: Inverse detection can only be used with BD metal detectors with conveyor and photo sensor. Products must pass the photo sensor one by one. Each product must reliably interrupt the photo sensor beam.

Note: Product has to be taught without metal even for inverse detection.

These settings will change their function if inverse detection is activated:

| METAL COUNTER | counts products WITHOUT metal |

| METAL REPORT | shows events WITHOUT metal |

| SHARKNET | NO-METAL events will get reported |

Presettings

Multiphase settings

Multiphase detection has to be enabled.

For further information refer to:

https://docs.cassel-inspection.com/md/howto-multiphase

SPEED mm/s settings

Choose one of these ways to set the correct SPEED mm/s:

- Set SPEED mm/s to the actual conveyor speed.

For further informatin refer to:

https://docs.cassel-inspection.com/md/speed-mm-s - Adjust AUTOSPEED

For further informatin refer to:

https://docs.cassel-inspection.com/md/autospeed-menu - Use ENCODER INPUT

For further information refer to:

https://docs.cassel-inspection.com/md/howto-encoder-input

PUSHER settings

Pusher has to be set according to setup instructions:

https://docs.cassel-inspection.com/md/howto-pusher-setup

Note: Set CAPTURE AREA mm to the distance in mm of the free gap between the signle product packs.

Minimum free gap between single product packs = 120mm

Minimum product length = 90mm

Safety margin = 30mm

Activation

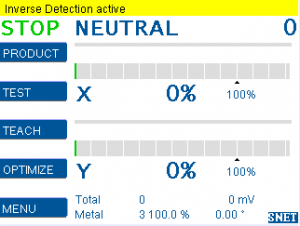

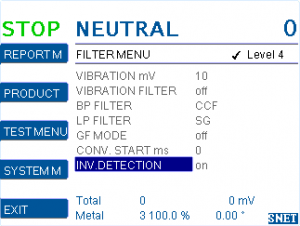

Set SYSTEM MENU > FILTER MENU > INV.DETECTION > on

Mainscreen will show a yellow notification bar indicating inverse detection is active:

Set sensitivity for inverse detection

Inverse detection is intended to be used for products with little or no product effect.

Thus products with metal object will generate a big signal, products without metal object will generate a small or no signal.

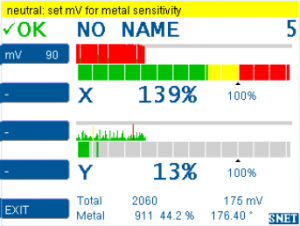

To ensure correct funtion of inverse detection the signal shown in the bar graph screen should be at 130-150% when passing a product with metal object.

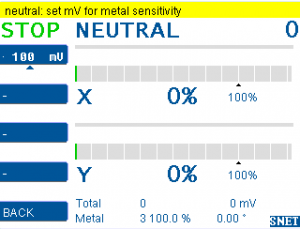

Set all products to neutral: PRODUCT MENU > PRODUCT IS… > neutral

Confirm with +/-.

Depending on the size of the metal included in the product, the signal may be very high.

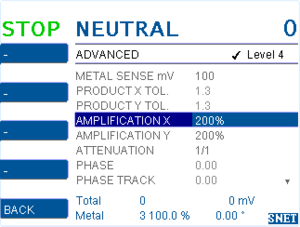

To decrease the signal significantly, decrease the amplification stepwise:

PRODUCT MENU > ADVANCED > AMPLIFICATION X% / Y%

Use OPTIMIZE function in the bar graph screen to fine adjust the %-signal strengh with mV.

Feed several different product packs with metal and make sure the signal value is well above 100%.

Feed several different product packs without metal and make sure the signal is well below 100%.

Comments 1

Comments are closed.