Encoder settings for speed and position management.

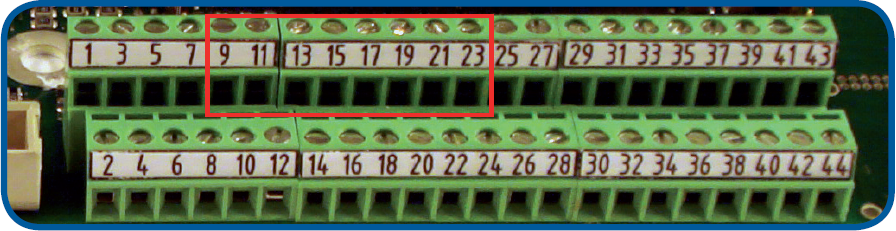

Wiring

Connect the encoder pulse signal to any of the inputs 1 to 8 on Shark mainboard.

Max input voltage = 24V

Max input frequency = 2kHz

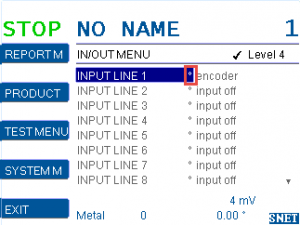

System menu settings

- Activate the encoder reading and pulse counting: SYSTEM MENU > IN OUT MENU > input = encoder

- Check the encoder signal input: SYSTEM MENU > IN/OUT MENU the little number 0 and 1 should toggle 1/0/1/0… when the encoder turns. The screen update rate is slower then the input counting, but at least you have to see some changes between 0 and 1.

Speed settings

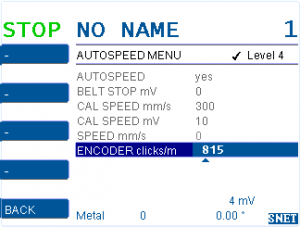

Set the encoder input pulses as distance value.

Example to determine a suitable distance value:

24V signal

256 pulses per 360 degree turn

Roller diameter 100 mm > Roller length = Pi*100 = 314 mm

256 clicks / 0.314 m = 815,28 clicks / 1.0 meter

Set ENCODER clicks/meter = 815.

SYSTEM MENU > AUTOSPEED MENU > ENCODER clicks/m

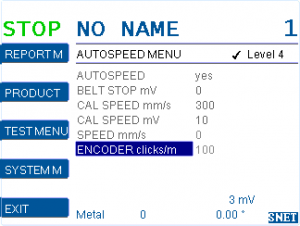

Automatic speed calculation

Activate automatic speed calculation

SYSTEM MENU > AUTOSPEED MENU > AUTOSPEED = YES

Function test

Check if SYSTEM MENU > SPEED mm/s shows the actual speed.

SPEED mm/s is automatically set according the encoder pulse frequency.

Further information

- The pulse counter is updated every 0.1 ms and the internal conveyor position for reject delay updates at the same intervall (position for logging metal alarms and trigger the reject).

- The speed calculation uses an interval of 500 ms to update the actual speed.

Reset encoder counter

Set any INPUT 1 to 8 = product LS

This setting requires 24V (high) input. A 0V pulse (high – low – high) will reset the encoder counter.

Comments 2

Comments are closed.