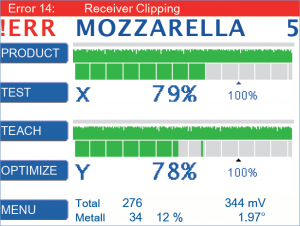

In case of an error:

- the Error-LED lights up,

- the screen indicates !ERR,

- an error message is displayed.

Note: Please write down the number of the error and talk to the company technician or call a service technician of CASSEL Messtechnik.

| Error # | Error Text | Cause | Remedy | Confirmation |

| Error 1: | Comp. Pre |

|

|

|

| Error 2: | Comp. Fine |

|

|

|

| Error 3: | Signal Clip |

|

|

|

| Error 4: | Reject |

|

|

|

| Error 5: | PVS Test Elapsed |

|

|

|

| Error 6: | Bin Full |

|

|

|

| Error 7: | Low Air |

|

|

|

| Error 9: | Keyboard |

|

|

|

| Error 10: | Memory |

|

|

|

| Error 12: | Check Belt |

|

|

|

| Error 13: | Output Wiring |

|

|

|

| Error 14: | Receiver Clipping |

|

|

|

| Error 15: | Transmitter Overload |

|

|

|

| Error 16: | Transmitter Voltage |

|

|

|

| Error 17: | Booster Error |

|

|

|

| Error 18: | Mat Height Input |

|

|

|

| Error 19: | Autospeed Input |

|

|

|

| Error 20: | License expires |

License for the metal detector has expired. Contact Cassel and indicate the 8-digit code to obtain full license. Follow these instructions: HowTo: License Code |

||

| Error 21: | Blockage | Digital Input ‘blockage’ for additional light sensor to detect jamming of products on conveyor. ‘Error 21 Blockage’ is generated if the light sensor is blocked permanently for more than 10 seconds. The error resets automatically if the light sensor is free for more than 3 seconds. |

||

| Error 22: | Bin Door | Digital input ‘bin door’ to check if the bin door is open for more than 5 minutes, if yes generate ERROR 22 ‘Bin Door’. | ||

| Error 23: | Photo Sensor |

Red error 23 message: See here for more information:

Yellow warning message: |

||

| Error 24: | No SharkNet | Parameter REPORT MENU→ERROR NO SHARKNET=no/yes that generates ERROR 24: NO SHARKNET if the connection to the Sharknet PC is lost for more than 120 seconds (default=no). ERROR 24 is reset automatically if the Sharknet connection is available again. |

||

| Error 25: | Too many rejects | Flap protection for GF Systems to detect and avoid too frequent flap operations (>15 operations per minute). Error 25 ‘Too many rejects’ which auto-resets after 30 minutes (for 1 Minute if error condition persists). |

||

| Error 26: | Sensor Cable Break | Sensor coil cables are broken or not properly connected to the control box electronics (mainboard). | ||

| Error 27: | Temp. Sensor Cable Break |

Sensor heads with temperatur based phase drift correction: temperatur sensor cable is broken or not properly connected. | ||

| Error 28: | Set DELAY mm > xxx |

This warning/error detects when the distance between metal detector and pusher is to short for the inspected product lengths. Note: ERROR 28 can be disabled/enabled in FACTORY MENU>UTILITIES>SIGNAL ROUTING>ERROR 28: DELAY = on/off |

||

| Error 29: | Emergency Stop |

Refer to IN/OUT MENU, input ‘e-stop’: HIGH: sets OUTPUT start conveyor to low. Conveyor start is prohibited |

||

| Error 30: | Detector Clipping |

Signal amplitude from the receiver coil is very much too large. The large signal must occur for a longer time. The time depends on the conveyor speed and is how long it takes for the product to move approx 64x of the tunnel height or width (whateveer is the smaller dim).

Reasons for error 30: Recommendation: Contact Cassel service for solving error 30. since version 1.51f12: Error 30 is available Auto Reset for error 30:

|

||