Additional scale factor to automatically scale TOL. X and TOL. Y during teaching a product.

How to change metal sensitivity:

Use MULTIPHASE TOL.X* and TOL.Y* to pre-set the teacharea size for all products, for all teachings.

Use OPTIMIZE > TOL.X and TOL.Y to change the teacharea size AFTER teach has been done, for this one product only.

The basic tolerances are set during teach by the PRODUCT IS… setting (e.g. 1.3 for dry). MULTIPHASE TOL.X*/Y* is multiplied with the basic tolerance to give the final used tolerance.

A proper adjustment of MULTIPHASE TOL.X*/Y* ensures a smooth teach. After teach no further manual settings of TOL. X and TOL. Y should be required. Instead, best possible stability along with good detection sensitivity should automatically be achieved. MULTIPHASE TOL.X*/Y* allows to adapt the teach to any product properties and variations.

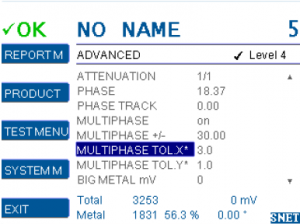

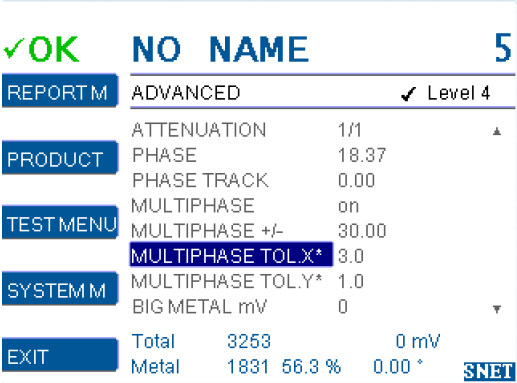

MULTIPHASE TOL.X*

Range: 1.0-9.9

Default: 3.0 (with TEACHAREA MODE = ellipse)

Default: 1.0 (with TEACHAREA MODE = contour)

Global or Individual per each product: Global setting

MULTIPHASE TOL.Y*

Range: 1.0-9.9

Default: 1.0 (with TEACHAREA MODE = ellipse)

Default: 1.0 (with TEACHAREA MODE = contour)

Global or Individual per each product: Global setting

Example #1:

PRODUCT IS … DRY 1.3

MULTIPHASE TOL X 1.5

MULTIPHASE TOL Y 1.0

TOL. X = 1.3 * 1.5 = 2.0

TOL. Y = 1.3 * 1.0 = 1.3

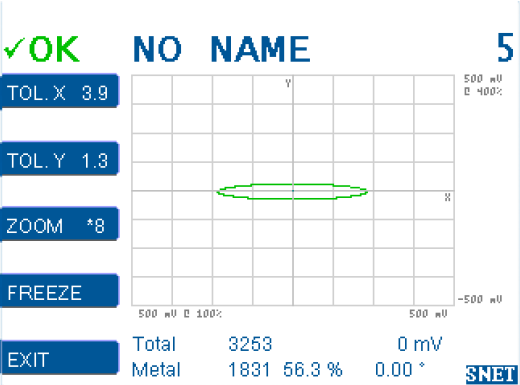

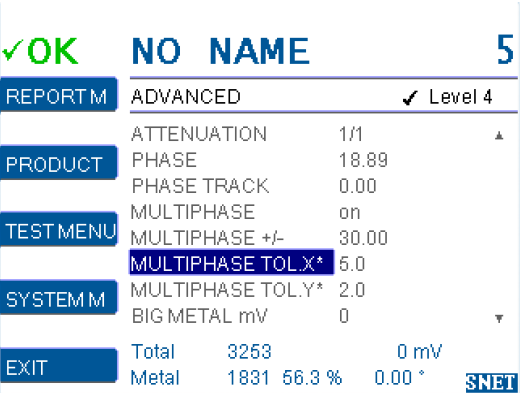

Example #2:

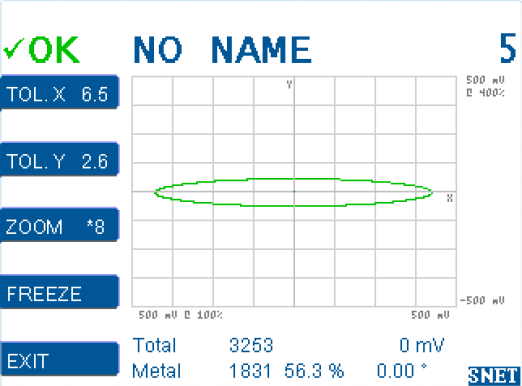

Moving MULTIPHASE TOL.X* from 3.0 to 5.0 increased TOL. X from 3.9 to 6.5.

Moving MULTIPHASE TOL.Y* from 1.0 to 2.0 increased TOL. Y from 1.3 to 2.6.

For further information refer to:

https://docs.cassel-inspection.com/md/howto-multiphase

Comments 1

Comments are closed.