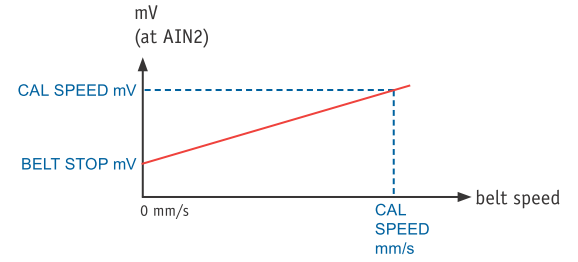

Automatic setting of SPEED mm/s according to an electrical signal on AIN2 (Input terminal #3).

Caution!

Only use the AUTOSPEED MENU after you ensured that a 0-10V (or optional 4 – 20 mA with a mA to V converter) speed signal is connected to the AIN2 input. The settings in the AUTOSPEED MENU define the relation between mV or mA and the resulting SPEED mm/sec. setting.

Caution!

A wrong setting for AUTOSPEEED can significantly diminish the metal detection sensitivity.

Caution!

These settings must be done before using AUTOSPEED.

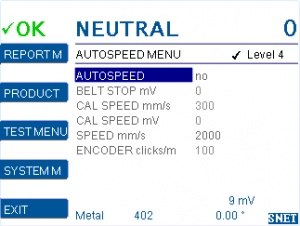

- BELT STOP mV : AIN2 input at 0 mm/sec. (conveyor stopped).

- CAL SPEED mm/s : Definition of the setpoint for CAL SPEED mV .

- CAL SPEED mV : AIN2 input at a conveyor speed of CAL SPEED mm/s.

AUTOSPEED

yes: The SPEED mm/s setting is automatically kept according to the AIN2 input.

AIN2 (input terminal #3) : Input terminal for the autospeed signal.

no: Enter manually a fix value as SPEED mm/s setting. Refer to SPEED mm/s in the SYSTEM MENU settings https://docs.cassel-inspection.com/md/system-menu

Default: No

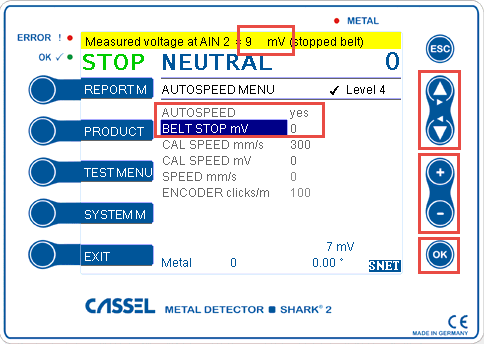

BELT STOP mV

Sets the calibration voltage for conveyor speed = 0 mm/s ( conveyor stopped).

NOTE: The yellow notification bar shows the current mV at AIN2 analogue input. Use the mV as shown in the yellow bar. This mV is different from what you would measure with a voltmeter, because there is a signal conditioner in between.

Stopp the conveyor. Take over the mV from the yellow notification bar by pressing at once + /- .

Default: 0

Range: 0 – 99990

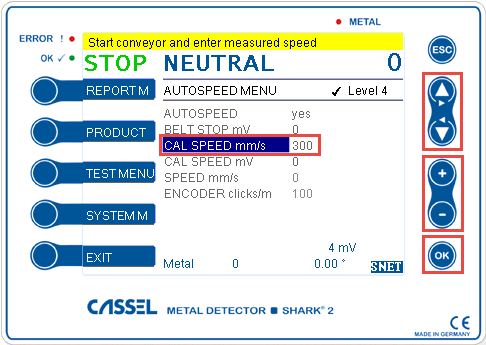

CAL SPEED mm/s

Enter a conveyor speed as definition of the setpoint for CAL SPEED mV. Recommended setting is 50% of maximum belt speed.

Note: Measure the current conveyor speed with a tachometer.

Default: 0

Range: 0 – 9999

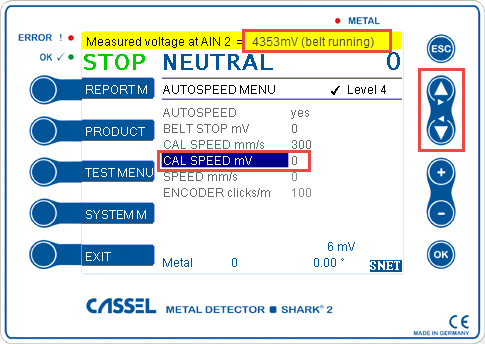

CAL SPEED mV

Sets the calibration voltage for conveyor speed CAL SPEED mm/s.

NOTE: The yellow notification bar shows the current mV at AIN2 analogue input. Use the mV as shown in the yellow bar. This mV is different from what you would measure with a voltmeter, because there is a signal conditioner in between.

Start the conveyor at speed same as CAL SPEED mm/s. Take over the mV from the yellow notification bar by pressing at once + /- .

Default: 0

Range: 0 – 99990

SPEED mm/s

Shows the resulting SPEED mm/s as calculated from input AIN2. For information only.

ENCODER clicks/m

Shows the frequency of the encoder in case an ENCODER is connected to an input.

For further information refer to:

https://docs.cassel-inspection.com/md/howto-encoder-input

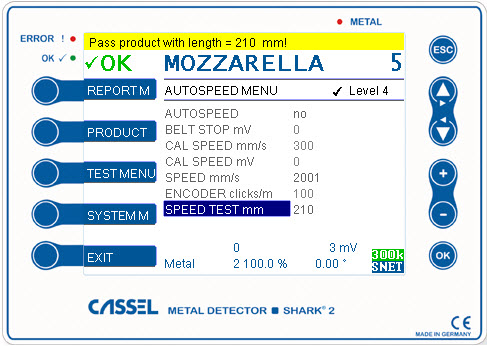

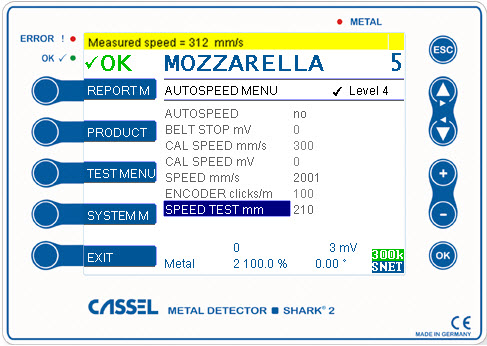

SPEED TEST mm

Available since SHARK 2A v1.50f21

To check if the SPEED mm/s setting is correct, follow these steps:

STEP 1/ Choose a non-transparent product

STEP 2/ Measure the product length

STEP 3/ Enter the product length in the SPEED TEST mm setting

STEP 4/ Start conveyor and pass the product straight through the photo sensor

The belt speed is calculated based on the product length and time required to pass the photo sensor.

Set this value for SYSTEM MENU > AUTOSPEED MENU > SPEED mm/s.

Note: If AUTOSPEED is set to yes, but the measured speed is not correct, check AUTOSPEED settings.

Comments 2

Comments are closed.