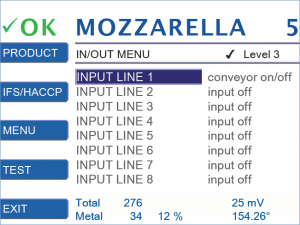

Setup of the input and output switching lines of the metal detector. Set up the parameters according to the devices connected to IN1 – IN8 and OUT1 – OUT 8 terminals on the mainboard.

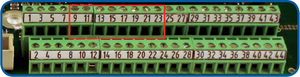

Terminals on SHARK mainboard corresponding to INPUT LINE 1 – INPUT LINE 8:

| INPUT LINE 1 = Terminal 9 | INPUT LINE 3 = Terminal 13 | INPUT LINE 5 = Terminal 17 | INPUT LINE 7 = Terminal 21 |

| INPUT LINE 2 = Terminal 11 | INPUT LINE 4 = Terminal 15 | INPUT LINE 6 = Terminal 19 | INPUT LINE 8 = Terminal 23 |

NOTE: A photo sensor connected to an input must be PNP type. PNP = The 24V are swicthed through to the photo sensor output.

Functions of INPUT LINE 1 – INPUT LINE 8:

| met/err reset | HIGH: Returns immediately to normal operation mode after METAL or ERROR. LOW: Normal operation Errors can be reset even if metal alarm is still pending. Resets ERROR and METAL at the same time. Note: Check setting of METAL CONTACT (in product menu > reject menu) for behavior of METAL outputs. |

| conveyor on/off | HIGH: Changes status of conveyor to START / STOP / RESET immediately LOW: Normal operation Belt control push button input (START / STOP / RESET) |

| e-stop | HIGH: sets OUTPUT start conveyor to low. Conveyor start is prohibited Sets ERROR 29: emergency stop. Sets OUTPUT error. Set OUTPUT MD inactive to inactive. LOW: Resets ERROR 29 emergency stop Conveyor can be started as normal Since version 1.51f |

| start teach | HIGH for minimum 2 sec.: Start TEACH LOW: Normal operation Required parameter settings: PRODUCT MENU > TEACH SETUP > TEACH EXTERN > yes |

| reject test | HIGH: Trigger reject device immediately. LOW: Normal operation |

| reject valid | HIGH: Normal operation LOW: After time set in SYSTEM MENU > BRC MENU > REJECT CONF ms: Reject confirmed The reject is validated when this input sees a minimum of two edges high/low or low/high after a ‘metal’ or ‘pusher’ output was activated. If no edge signal within REJECT CONF ms after METAL OUT , ERROR 4 Reject is triggered. For two digital inputs ‘reject valid‘ in the IN/OUT MENU, both inputs have to see an edge signal (AND logic, typically used with InLiquid, InMeat). Also refer to the ‘bin full‘ input, which can also be used for reject validation. |

| reject sync | HIGH: Normal operation LOW: Photo sensor triggers pusher to product centre Required parameter settings: PRODUCT MENU > REJECT MENU > METAL CONTACT> push1 or push2 |

| reject safety | HIGH: Normal operation LOW: Reject device is locked in position NORMAL, e.g. during cleaning. |

| keypad lock | HIGH: Keyboard is locked, no data entry possible. LOW: Normal operation Typical application: Key switch. |

| low air | HIGH: Normal operation LOW for more than 100ms: Triggers ERROR 7 Low Air Required parameter settings: SYSTEM MENU>BRC MENU>LOW AIR>YES Monitors compressed air. |

| start cip | HIGH: Activates CIP mode immediately LOW: Normal operation Required parameter settings: SYSTEM MENU > CIP MENU |

| bin full | HIGH: Normal operation LOW: For more than 30 sec.: Triggers ERROR 6 Bin Full (set duration after which ERROR is triggered at SYSTEM MENU > BRC MENU > BIN ERROR sec.) Monitors reject bin. Input ‘bin full‘ can also be used for reject validation AND for bin full. Reject validation: When there are two digital inputs ‘bin full‘ configured in the IN/OUT MENU, at least one of the two inputs has to generate an edge to validate the reject (OR-logic, typically used for BD). The bin full functionality remains unchanged with two inputs, i.e. if one of the two inputs is blocked for more than 30 seconds the ERROR 6 Bin Full is triggered. (set duration after which ERROR is triggered at SYSTEM MENU > BRC MENU > BIN ERROR sec.) If less than two of these inputs generate an edge signal within REJECT CONF ms, ERROR 4 Reject is triggered. Required parameter settings: SYSTEM MENU>BRC MENU>BINFULL>YES |

| met count reset | HIGH: Resets METAL COUNTER after 3 seconds LOW: Normal operation |

| false trip | HIGH: Sends a false alarm message to the SHARKNET® software |

| product 120 | HIGH: PRODUCT NR. is set to 120. LOW: PRODUCT NR. is set to original number. Allows fast product switching if the frequency, attenuation and amplification settings do not change from one product to the other. The fast switch time is then 0.2 seconds, while normally switch time is 1.5 to 2.0 seconds. Fast switch is available since version 1.51f05. Required settings: PRODUCT MENU > TEACH SETUP > REMOTE PRODUCT > no |

| met/err key | HIGH: Returns to normal operation mode after METAL or ERROR (only available with option: key switch). Note: Check setting of METAL CONTACT (in product menu > reject menu) for behavior of METAL outputs. LOW: Normal operation If this input is configured, auto reset of the errors BIN FULL, LOW AIR , BIN DOOR and BLOCKAGE are disabled and thus can only be reset by key switch. Only available with key switch. |

| booster ok | HIGH: Normal operation LOW: Triggers ERROR 17 Booster Error Note: Only change this input when advised by CASSEL. Monitors booster. |

| belt splice | HIGH: Sets sensitivity to SPLICE SENSE mV LOW: Sets sensitivity to METAL SENSE mV |

| product LS | Counts product packs (profile=BD). Resets the encoder counter (profile=COMBI). Refer to https://docs.cassel-inspection.com/md/input-product-ls |

| test no reject | HIGH: Activates metal test mode LOW: Normal operation (only with option: key switch). During test mode the conveyer is immediately stopped when metal ist detected (output ‘error CW‘) – however, the metal alarm is neither counted nor entered in the event report. Timeout of the test mode is controlled by SYSTEM MENU>CIP MENU>CIP Timeout min – after this time has elapsed normal metal detection continues. While the test mode is active TEST is displayed. |

| CW rejects | HIGH: Signal to checkweigher in case of metal alarm. LOW: Normal operation Can also be used together with one or two ‘reject valid‘ inputs as reject validation for the checkweigher reject. In this configuration ( ‘reject valid‘ together with ‘CW rejects‘)the reject valid timeout timing starts with ‘CW rejects‘ activation – not with the ‘metal‘ or ‘pusher‘ output pusher activation. |

| start pvs | HIGH: Starts pvs test LOW: Normal operation |

| blockage | HIGH: Normal operation LOW: ERROR 21 Blockage shows up if photo sensor is interrupted/blocked for more than time set in SYSTEM MENU>BRC MENU>BLOCKAGE sec |

| pitch cw | HIGH: Unblocked light sensor for measuring of product pitch. Required parameter settings: SYSTEM MENU>BRC MENU |

| encoder | Input for impulse from rotary encoder to meassure conveyor belt speed. For further information refer to: https://docs.cassel-inspection.com/md/howto-encoder-input |

| bin door | HIGH: If bin door is open ERROR 22 bin door shows up. LOW: Normal operation |

| quick teach | HIGH: TEACH MODE is set to ‘quick‘ and teach will be started LOW: Normal operation |

| product 0-N | HIGH: High product number LOW: Low product number Product switch binary coded. LOW bits = low product number For further information refer to: https://docs.cassel-inspection.com/md/howto-remote-product-bitwise |

| batch count | HIGH: Input signal for start of a new batch LOW: Normal operation |

| conveyor on | HIGH: A short pulse sets OUTPUT start conveyor to high LOW: Normal operation For conveyor belt control where start and stop are two separate push buttons or 24V plc signals. Connect a START push button (or 24V start pulse from plc) to this input. |

| conveyor off | HIGH: A short pulse sets OUTPUT start conveyor to low LOW: Normal operation For conveyor belt control where start and stop are two separate push buttons or 24V plc signals. Connect a STOP push button (or 24V stop pulse from plc) to this input. |

| MD inactive | HIGH: Switches metal detector to inactive (detection deactivated), transmitter will be switched off. LOW: Normal operation CAUTION: No metal detection while active!!! |

| input off | HIGH: Input is not active LOW: Input is not active |

| timer start | HIGH: Starts timer delay function. LOW: Normal operation. |

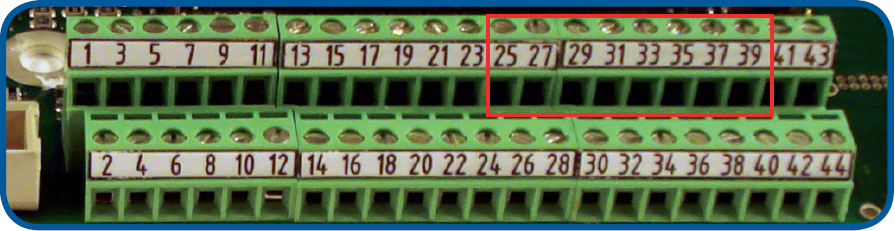

Terminals on SHARK mainboard corresponding to OUTPUT LINE 1 – OUTPUT LINE 8:

| OUTPUT LINE 1 = Terminal 25 | OUTPUT LINE 3 = Terminal 29 | OUTPUT LINE 5 = Terminal 33 | OUTPUT LINE 7 = Terminal 37 |

| OUTPUT LINE 2 = Terminal 27 | OUTPUT LINE 4 = Terminal 31 | OUTPUT LINE 6 = Terminal 35 | OUTPUT LINE 8 = Terminal 39 |

Functions of OUTPUT LINE 1 – OUTPUT LINE 8:

| metal | HIGH: Metal detected LOW: Normal operation |

| metal inverse | HIGH: Normal operation LOW: Metal detected |

| error | HIGH: Normal operation LOW: Detector is not in normal operation |

| error inverse | HIGH: Detector is not in normal operation LOW: Normal operation |

| met+err | HIGH: Metal alarm or unit not in normal operation LOW: Normal operation |

| met+err inv. | HIGH: Normal operation LOW: Metal alarm or unit not in normal operation |

| metal zero del | HIGH: If metal detected, no DELAY mm for metal alarm LOW: Normal operation Typical application: IN Meat or IN Liquid |

| metal lock | HIGH: After one or more metal alarms until reset manually by digital input ‘met/err reset’ or ‘met/err key’ LOW: Normal operation |

| big metal | HIGH: Normal operation LOW: Big metal piece is detected The big metal output is subjected to the delay and duration timing settings. |

| small metal | HIGH: Small metal piece is detected LOW: Normal operation Configures the output line for signalling small metal events |

| met-2 | HIGH: Metal detected LOW: Normal operation METAL CONTACT = met-2: Metal detected: OUTPUT metal = low, OUTPUT met-2 = high Normal operation: OUTPUT metal = low, OUTPUT met-2 = low METAL CONTACT any setting different from met-2: Metal detected: OUTPUT metal = high, OUTPUT met-2 = low Normal operation OUTPUT metal = low, OUTPUT met-2 = low |

| pusher 1/3 | HIGH: Reject LOW: Normal operation Used for linear and transversal pusher. The outputs metal and pusher switch to active at the same time: However, pusher switches back to inactive already after 1/3 of the time of DURATION ms (but at least 40 ms). This way a pneumatic pusher is able to return to normal position during DURATION ms. |

| pusher 1/1 | HIGH: Reject LOW: Normal operation Used for air pusher. Pusher stays active for DURATION ms. |

| pusher clocked | HIGH: Stakkato reject LOW: Normal operation Pusher is activated several times e.g. pneumatic pusher. Keyword: stakkato |

| start conveyor | HIGH: If conveyor on/off received a start signal LOW: Belt stop |

| conv. forward | Internal function, not for common use |

| conv. reverse | Internal function, not for common use |

| pv test | HIGH: Next test is due. Last sensitivity test was more than PV FREQ HOURS ago. LOW: Normal operation |

| pvs active | HIGH: Set while the actual PVS TEST is being performed. LOW: Normal operation Signal can be used to trigger the test piece reject for special applications |

| pvs ok | HIGH: 3 seconds pulse after each successfull passing of a Fe, NFe, SS test piece LOW: Normal operation |

| pvs error | HIGH: 10 seconds pulse after failed of passing one test piece (BIG SIGNAL, test piece signal was too large). Pass again the same fe/nfe/ss but with a correct size. 1.75 seconds pulse if the entire PVS routine is considered to be failed. PVS ends and PVS active is stopped after this. LOW: Normal operation |

| pvs FE | HIGH: Signal as long as PVS TEST requests FE testing LOW: Normal operation |

| pvs NFE | HIGH: Signal as long as PVS TEST requests NFE testing LOW: Normal operation |

| pvs SS | HIGH: Signal as long as PVS TEST requests SS testing LOW: Normal operation |

| product timeout | HIGH: As long as a timeout is active for PROD.TIMEOUT s. LOW: Normal operation Related parameter settings:PRODUCT MENU>ADVANCED>PRODUCT TIMEOUT s |

| dual freq | For dual frequency detectors only. |

| teach confirm | HIGH: TEACH ended successfully (“TEACH successfull” displayed) LOW: Normal operation |

| teach active | HIGH: TEACH is active LOW: Normal operation Signals if the teach process is still active or finished. |

| cip out | HIGH: Detector is in CIP mode LOW: Normal operation |

| booster on | HIGH: Booster on LOW: Booster error Output switches to HIGH with few seconds time delay after switching on the Shark 2A Electronic. Output switches to LOW at ERROR 17 Booster Error After reset Error 17 Booster Error Output switch to HIGH again. |

| reject@on | HIGH: Rejects products from conveyor after a power off/on cycle and after error confirmation. The signal remains active for the distance configured by reject parameter PRODUCT MENU>REJECT MENU>DELAY mm LOW: Normal operation |

| bin full | HIGH: Triggers ERROR 6 bin full LOW: Normal operation |

| metal CW | HIGH: Metal detected – active for 140ms LOW: Normal operation |

| error CW | HIGH: Normal operation LOW: Detector is not in normal operation When metal test mode is activated via key switch, also when metal is detected. To stopp the conveyor of the checkweigher when metal is detected during test mode. |

| pitch error cw | HIGH: The pitch between two products is smaller than PITCH mm CW, signal lasts for a distance of twice the pitch treshold. LOW: Normal operation |

| MD active | HIGH: Ready for metal detection LOW: Not ready for metal detection MD active is LOW in these cases: – An error is shown – After power supply on, until calibration is completed – While changing a product number (since version 1.51c) – For conveyor system with AUTOSPEED = yes: conveyor does not run |

| output off | Output not active. Output remains LOW. |

| timer OFF delay | HIGH: Immediately when INPUT timer start is high. LOW: When INPUT timer start is low for longer than timer OFF delay ms. |

| timer ON delay | HIGH: When INPUT timer start is high for longer than timer ON delay ms. LOW: Immediately when INPUT timer start is low. |

| heartbeat | HIGH: 125 ms per second LOW: 875 ms per second The heartbeat output confirms that the metal detector firmware is running. Available since version V1.51e23. |

| teach fault | HIGH: ‘teach extern’ completed unsuccessfull, 500 ms pulse low/high/low LOW: ‘teach extern’ compleed successful, remains low ‘teach extern’ starts either by input ‘start teach’ or a Sharknet-2 command. Available since version V1.51e23. |

| pw level 1 pw level 2 pw level 3 | pw_level1 – 24V if password for level 1, 2, 3 or 4 was entered pw_level2 – 24V if password for level 2, 3 or 4 was entered pw_level3 – 24V if password for level 3 or 4 was entered A pw_level output remains 24V as long as the password level remains logged in. A pw_level output returns to 0V after the password level got logged out. |

| VtoF converter | This output takes the speed signal measured at the S2a analog input and converts it to a pulsed signal with 500 clicks per meter on a configurable digital output. This output signal can then be used to distribute the exact same speed signal to an encoder input on one or multiple S2a units for exact and consistent position measurement. Available since version V1.52f https://docs.cassel-inspection.com/uncategorized/output-vtof-converter |

Comments 2

Comments are closed.